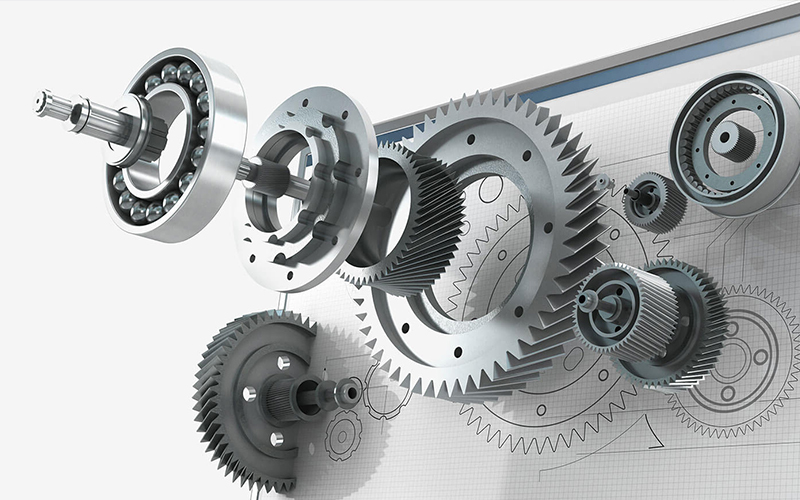

Linqing Xinhong Bearing Co., Ltd is a professional manufacturer and distributor of various types of bearings. Our product range includes deep groove ball bearings, cylindrical roller bearings, tapered roller bearings, self-aligning ball bearings, spherical roller bearings, angular contact ball bearings, and more......

Bearing

Type

Our professional team of engineers and technical staff ensures our position in the industry. While strengthening internal management, we establish a foothold in the market with better quality and lower prices.

Rich models

Complete variety

Bearing consultant

Team Services

The specific reasons for the natural wear of the b....

There are dozens of types of bearings on automobil....

Before the bearing is installed, appropriate measu....

WhatsApp

WhatsApp